No, Industry 4.0 should not be responsible for the next industrial layoff

Digital transformation affects all areas of the company. As consumers, we see it through the generalization of online commerce after having experienced the digitalization of our social relations.

Although less visible, the industrial world is no less spared by this transformation. Familiar with revolutions, it has even named this transformation Industry 4.0. While some dream of this transformation, others fear it particularly because of its consequences on human resources, the extent of which is sometimes difficult to anticipate.

In the following three articles, Christelle Villard, Xavier Le Page and Antoine Aubois, respectively Manager, Senior Manager and Partner at Akoya Consulting, a strategy consulting firm dedicated to human issues, share their observations on the major impacts of Industry 4.0 on the workforce, jobs and skills.

Our goal is to go beyond preconceived ideas without naivety or cynicism, but always with benevolence and pragmatism.

Flexibility and reduction of drudgery on production lines

The reason Industry 4.0 has become so popular is that it brings many benefits to the organization implementing it. It can provide consumers with increasingly personalized products whose production they can follow in real time. This means greater line flexibility, even more frequent cycle changes, sometimes even unit changes. Flexibility is also made possible by the installation of numerous sensors capable of informing operators in real time of the state of the machine, the progress of production, the quality of the products, etc.

However, as with previous industrial revolutions, Industry 4.0 also brings new machines that can take over tasks previously performed by human operators. These are tasks that had less added value or endangered the operator’s health in the long term. Henceforth, it is AGVs (Automated Guided Vehicles) that move raw materials and finished products from one point to another on the site. The cobots (collaborative robots) will carry out the most repetitive manipulations directly on the lines. Finally, a machine is now capable of alerting in real time when it deviates from its operation rather than waiting for the operator to notice it after sometimes long hours of passive surveillance.

A clear but relative impact in terms of employment

If the reduction of the drudgery of human work is worthy, what about the consequences in terms of employment?

Based on our experience from working with industrial sites around the world, we have observed the implementation of Industry 4.0 means an 8 to 10% downward on the number of jobs at a site. This impact is nevertheless far from an industrial dystopia operated exclusively by robots.

However, it is exactly at this stage that we still see many decision-makers making a dangerous shortcut: 8 to 10% job cuts = a reduction of 8 to 10% of the workforce. Here is why this shortcut is wrong and can result in costly and even dangerous decisions.

Effects that can often be avoided with no social damage

Despite all the goodwill in the world, once it is decided, the Industry 4.0 project takes time to be implemented. According to our observations it can take between 2 to 4 years. This timeframe offers enough time to anticipate and use the natural attrition of the population to absorb all or part of these job reductions.

This simplified example below, far from being a caricatured one, illustrates the details of the reasoning.

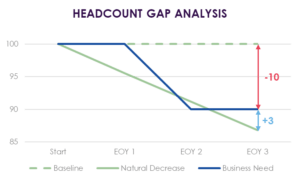

Let’s take a site of 100 people where a project will lead to a reduction of 10 positions in 2 years time (dark blue curve). If we were to stop there, this would mean that we would have to implement a departure plan for 10 people to avoid overstaffing in the long term (red arrow). However, over the next 3 years, 3 people per year should retire from this site and 1% of the remaining population might leave the site for reasons that are not under company’s control (e.g. resignation). Thus, without taking more decisions and especially without taking replacement measures, the site will only have 87 people left in the next 3 years (green curve). Instead of having a surplus of 10 people, we actually have a shortage of 3 people to fill (blue arrow).

Therefore, the action to be taken by the site will consist of replacing only 3 of the 13 expected departures, without forcing any of them. Far from neglecting the complexity of not-replaced departures and the trauma that this can represent for departing employees, it is nevertheless possible to avoid a departure plan that is furthermore traumatic and costly, that can lead to a major loss of skills.

Besides its social benefits, this approach is intended to lead manufacturers to rethink their vision with Industry 4.0 projects. Carrying out this type of analysis enables them to place their project at the right time with regard to the expected evolution of the population. When the time comes to implement it, the often substantial budgets that should have been devoted to financing redundancy plans can be advantageously redirected to skills development. The latter is another key subject for Industry 4.0 project success that will be discussed in an upcoming article.

Related articles:

Article 2 “No, Industry 4.0 will not replace all the industrial jobs”

Article 3 “No, Industry 4.0 will not require operators to become Data Scientists”

Contact our experts to discuss the human impact of the Digital Factory

Antoine Aubois Co-founder

Xavier Le Page Senior Manager

Christelle Villard Manager